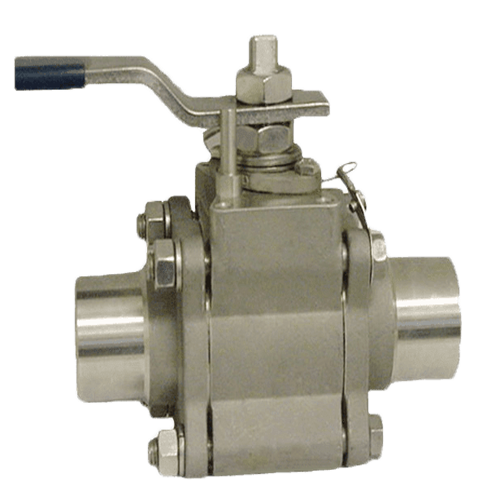

ci Ball valve

ci Ball valve Specification

- Structure

- Control

- Usage

- Industrial

- Media

- Water

- Size

- Different Sizes Available

- Product Type

- BALL VALVE

- Color

- Silver

ci Ball valve Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 1 Week

- Sample Available

- No

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About ci Ball valve

-

Quick Quarter-Turn Operation: Provides fast, efficient shut-off and on/off control.

-

Excellent Sealing Capability: Offers tight, leak-proof closure, making them ideal for gas and fluid applications where positive shut-off is critical.

-

Durability and Longevity: Constructed from robust materials like stainless steel, carbon steel, brass, bronze, or PVC, ensuring long service life in demanding environments.

-

Versatile Applications: Suitable for a wide range of industries, including oil and gas, chemical processing, water treatment, HVAC, and more.

-

Compact Design: Their relatively small footprint allows for installation in confined spaces.

-

Low Maintenance: Generally require minimal maintenance due to their simple and robust design.

-

Bi-directional Flow: Many designs allow flow in both directions, simplifying installation and reducing the need for multiple valve types.

Common Types and Configurations:

-

Body Styles:

-

One-Piece: Economical, often considered "throwaway" valves due to difficulty in repair.

-

Two-Piece: Body sections bolted or threaded together, allowing for easier maintenance and seat replacement.

-

Three-Piece: Allows for the central body section containing the ball and seats to be removed from the pipeline without disturbing the end connections, facilitating in-line service and repair.

-

-

Ball Designs:

-

Floating Ball: The most common type, where the ball is held in place by the compression of the seats, allowing it to "float" slightly and provide a tight seal.

-

Trunnion Mounted Ball: Ideal for larger sizes and higher pressures, the ball is mechanically anchored at the top and bottom, reducing operating torque and seat wear.

-

-

Port Design:

-

Full Port (Full Bore): The bore (hole) through the ball is the same size as the pipeline, minimizing pressure drop and allowing for pigging.

-

Reduced Port (Reduced Bore): The bore is smaller than the pipeline, resulting in a slight pressure drop but offering a more compact and economical design.

-

V-Port: Features a V-shaped opening in the ball or seat, allowing for more precise flow control (throttling).

-

-

End Connections:

-

Threaded (NPT, BSPT, BSPP): Common for smaller sizes.

-

Flanged (ASME B16.5): Used for larger sizes and higher pressures, providing a secure, bolted connection.

-

Socket Weld (SW): Permanent welded connection for high-pressure and high-temperature applications.

-

Butt Weld (BW): Permanent welded connection offering maximum strength and minimal leakage points.

-

-

Operation:

-

Manual (Lever/Handle): Simple, cost-effective, and commonly used for general on/off applications.

-

Actuated (Pneumatic, Electric, Hydraulic): For automated control, remote operation, and high-cycle applications.

-

Available Options (depending on model):

-

Fire-Safe Design: Features secondary metal seats to maintain a seal in case of soft seat burnout during a fire.

-

Anti-Static Device: Ensures electrical continuity between the ball, stem, and body, preventing static charge build-up, especially important for flammable media.

-

Blow-Out Proof Stem: Designed with a shoulder to prevent the stem from being ejected under pressure.

-

Cavity Pressure Relief: Mechanisms to prevent pressure build-up in the body cavity, which can damage the valve.

-

Extended Stem: For applications with high or low temperatures, or where the valve is in an insulated pipeline, to move the actuator away from the body.

-

Seat Materials: PTFE, RPTFE, PEEK, Nylon, Devlon, Metal Seats (for high temperature/abrasive services).

-

Body Materials: WCB, CF8M (SS316), A105, A182 F304/F316, Hastelloy, Monel, etc

Engineered for Versatility

The ci Ball Valve is versatile, handling various industrial water control applications with ease. The forged construction ensures resilience against pressure fluctuations and repeated use. Whether you need precision control or a robust shut-off mechanism, our ball valve adapts to your process requirements.

Precision Control in Industrial Environments

Designed for medium pressure systems, this valve offers accuracy in water flow regulation. Its threaded connection makes installation quick and minimizes downtime, helping industries maintain uninterrupted operations. Different size options enable seamless integration with existing piping layouts.

FAQ's of ci Ball valve:

Q: How does the ci Ball Valve support reliable water control in industrial environments?

A: The ci Ball Valve utilizes a forged structure and precise control mechanism, ensuring stable performance for medium-pressure water applications. Its robust design allows for smooth operation, minimizing risk of leaks and ensuring long-term reliability.Q: What materials and finishes are used in the construction of the ci Ball Valve?

A: The valve is made from high-quality forged materials and features a durable silver finish. This construction enhances its resistance to corrosion and wear, making it ideal for industrial water systems.Q: When should you consider using this ball valve in your water processing line?

A: This ball valve is best suited for medium-pressure water systems where controlled flow and reliability are essential. It is particularly beneficial in applications requiring frequent operation or precise flow modulation.Q: Where can the ci Ball Valve be installed within industrial operations?

A: The valve is designed for flexibility and can be installed at various points in industrial water control systems, such as main supply lines, branch circuits, or any location needing controlled flow. Its threaded design ensures easy integration into existing setups.Q: What is the process for installing the ci Ball Valve?

A: Installation is straightforward due to its standard threading. Simply ensure that the piping threads match and use appropriate sealing tape for a secure fit. Standard processing of the valve ensures consistent compatibility and easy maintenance.Q: How does using a forged ci Ball Valve benefit industrial users?

A: Forged ci Ball Valves offer enhanced strength and longevity, reducing maintenance needs. Their durable construction withstands challenging industrial conditions, ensuring consistent performance and reducing downtime.Q: What size options are available and how do they cater to different industrial needs?

A: The valve is available in multiple sizes to accommodate varying pipe diameters, allowing industries to choose the best fit for their specific application without compromising on operational efficiency or reliability.

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves Category

VIP Ball Valve

Price 850 INR / Piece

Minimum Order Quantity : 1 Piece

Media : Other, Water, Oil, Gas

Material : Other, Polypropylene (PP)

Finish : Smooth

Application : Industrial, Domestic, Agricultural

Zoloto Ball Valve

Price 500.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Media : Water

Material : Stainless Steel

Finish : Polished & Coated

Application : Water

RB Italy Ball Valve

Price 850 INR / Piece

Minimum Order Quantity : 1 Piece

Media : Water

Material : Stainless Steel

Finish : Polished & Coated

IMI Ball Valve

Price 1950 INR / Piece

Minimum Order Quantity : 1 Piece

Media : Water

Material : Stainless Steel

Finish : Polished & Coated

Application : Industrial Flow Control

Send Inquiry

Send Inquiry Send SMS

Send SMS